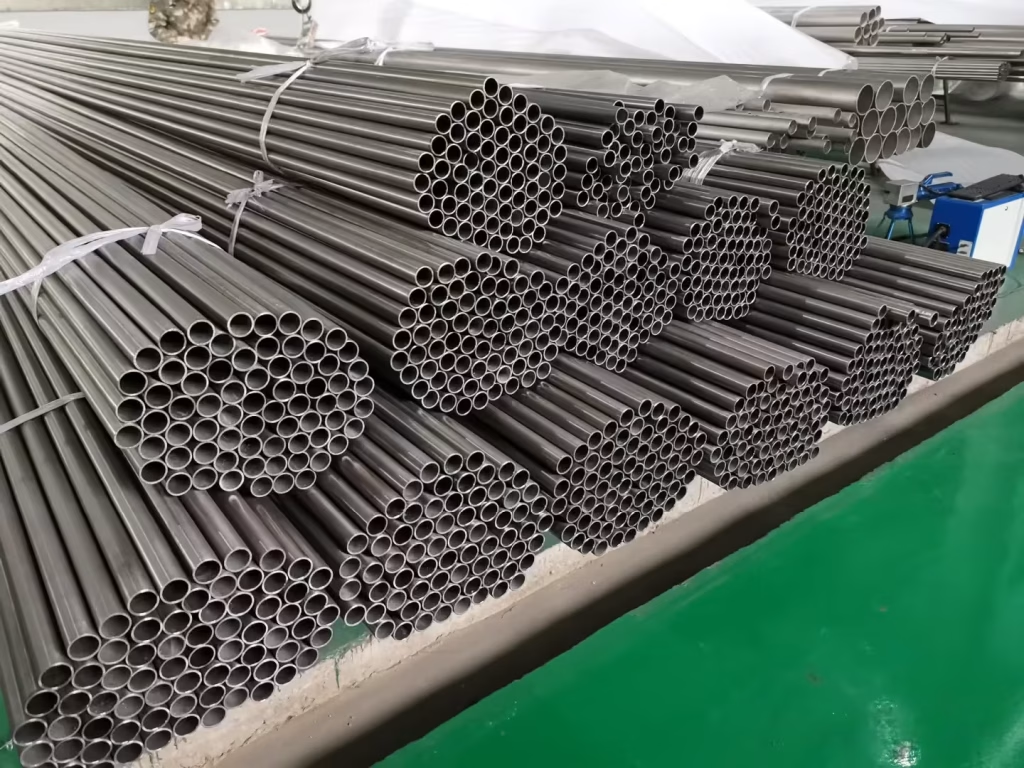

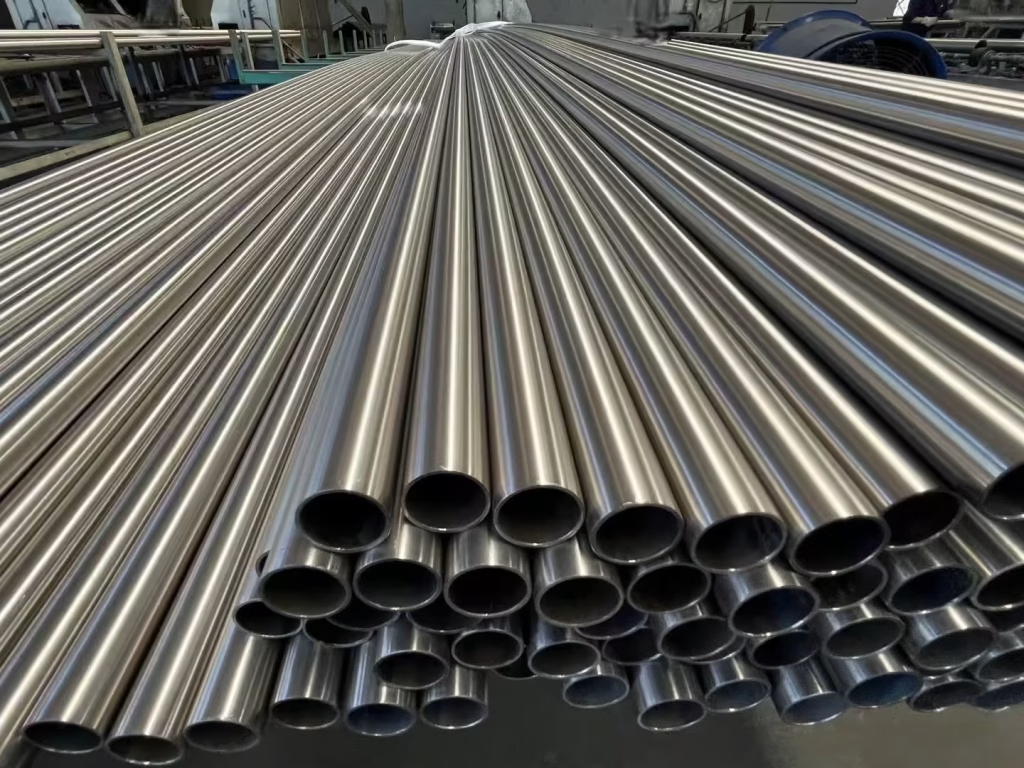

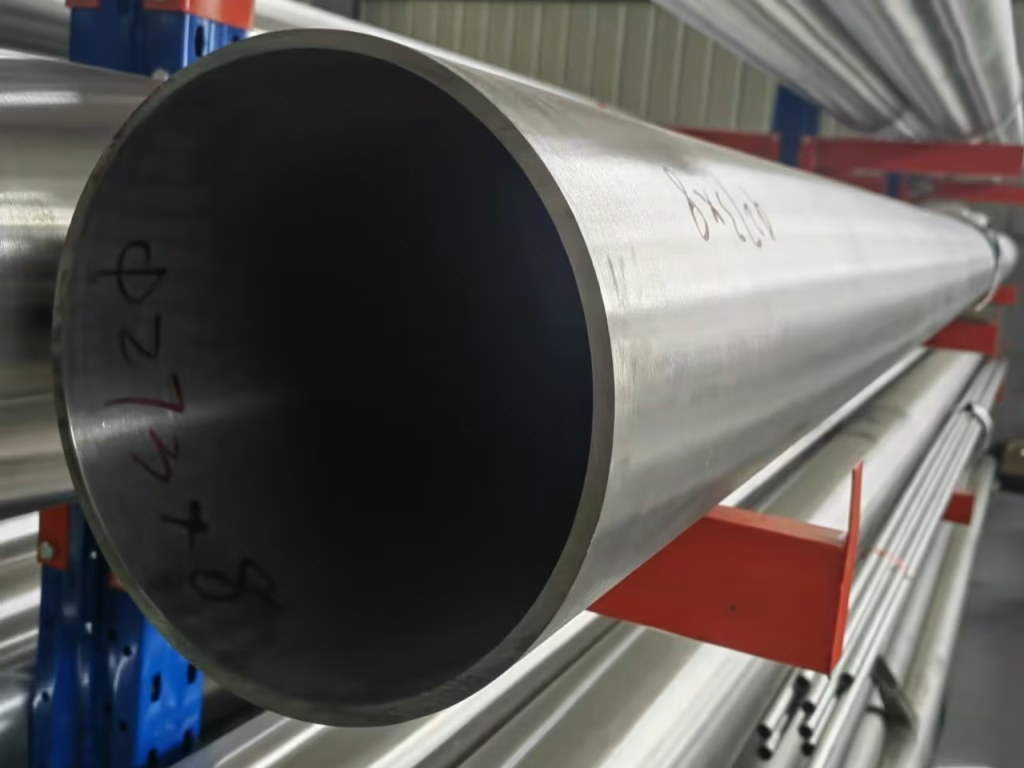

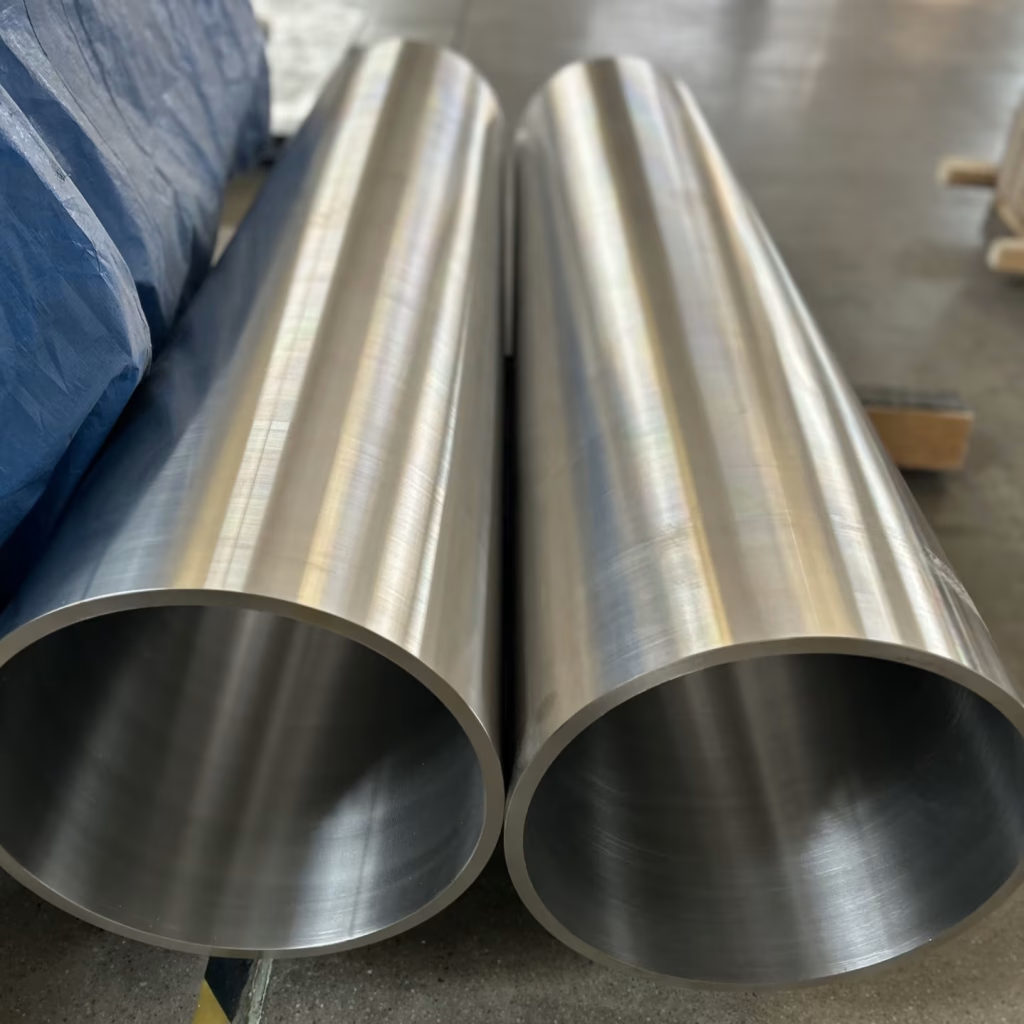

Titanium pipe / tube

💰 Direct Factory Pricing

Work directly with the manufacturer and skip unnecessary markups. Our factory-to-customer model ensures the most competitive titanium pricing, giving you a stronger margin advantage.

🚀 Fast and Flexible Delivery

With well-managed stock and efficient air freight partnerships, we deliver on your schedule — whether it’s a bulk shipment or a single urgent order. No minimum order quantity (MOQ) required.

🧾 Certified and Transparent Quality

Operating under ISO 9001:2015 certification, every batch is backed by a Mill Test Certificate (MTC). We also welcome third-party inspections to verify material integrity and compliance.

|

Grade |

GR1, GR2, GR3, GR4, GR5, GR7, GR9, GR11, GR12, GR23, etc. |

|

BT |

BT1-00, BT1-0, BT1-2, BT6, BT3-1, ПТ-3В, BT6C, BT25, ВТ25У, etc. |

|

Welded Pipe Sizes: |

OD(90-1020mm)WT(0.5-50.0mm)L(as required) |

|

Seamless Pipe Sizes: |

OD (3 – 520 mm)WT(0.4 – 30 mm)L(as required) |

|

Standard |

ASTM B337, ASTM B338, ASTM B861, ASTM B862, GB/T 2924-2007, GB/T3625-2007 |

|

GOST 22897-86, GOST 24890-81, GOST 21945-76 | |

|

Test |

Eddy Current Test, Hydrostatic Test, UT, Penetrant Test, Air underwater pressure Test, PMI Test,Spectro Test, Intergranular Corrosion Test, Sharpy Impact Test, Hardness Test, Tension Test(Elongation, Yield Strength, Tensile Strength), Flarring Test etc. |

|

Ends |

PE/Plain Ends, BE/Beveled Ends |

Direct from the Manufacturer

At Shaanxi Hanye Iron and Steel Co., Ltd, an ISO 9001:2015 certified producer, we manufacture and supply a complete range of titanium pipes and tubes designed for demanding industrial, chemical, marine, and aerospace applications.

With factory-direct pricing, certified quality, and fast worldwide logistics, we simplify your titanium procurement and deliver value you can rely on.

Why Work with Us — Reliable Supply, Proven Quality

🏭 Direct-from-Factory Pricing for Maximum Value

By sourcing directly from our Baoji-based production facility, you eliminate distributor markups and gain access to the most cost-efficient titanium solutions.

We offer both seamless and welded tubes, competitively priced to enhance your project’s profitability.

✅ Strict Quality Control & Full Traceability

Every tube and pipe is produced from high-purity titanium ingots and tested through ultrasonic, eddy current, and hydrostatic inspections to guarantee structural integrity.

A Mill Test Certificate (MTC) is issued with each shipment, ensuring full material traceability and compliance with international standards.

⚙️ Flexible Orders with No MOQ

Whether you need a prototype batch or a large production run, we operate with no minimum order quantity.

Our ready stock of standard dimensions and efficient air-freight network ensure your order arrives on time, anywhere in the world.

🧩 Comprehensive Range & Expert Technical Support

We supply titanium pipes and tubes in multiple grades, wall thicknesses, and diameters, both seamless and welded.

Our engineering team provides professional guidance to help you select the right material for your specific application and budget.

Technical Specifications

Product Types & Size Range

Seamless Titanium Pipes / Tubes

Best suited for high-pressure, precision, or critical service applications.

- Outer Diameter (OD): 3 mm – 520 mm

- Wall Thickness (WT): 0.4 mm – 30 mm

- Length: Up to 18 m

Welded Titanium Pipes / Tubes

An economical option for larger diameters and low-to-medium pressure use.

- Outer Diameter (OD): 90 mm – 1020 mm

- Wall Thickness (WT): 0.5 mm – 50 mm

- Length: Up to 15 m

Material Grades

- Commercially Pure Titanium (Gr1, Gr2, Gr3, Gr4):

Excellent corrosion resistance and formability — ideal for chemical processing, desalination, and marine environments. - Titanium Alloys (Gr5, Gr7, Gr9, Gr23, etc.):

High strength, fatigue resistance, and stability for aerospace, medical, and high-performance industrial use.

Standards & Compliance

All pipes and tubes are manufactured in accordance with:

- ASTM B337 / B338 / B861 / B862

- Available per ASME, DIN, and JIS standards upon request.

Customization Options

We offer full customization to meet your project’s needs:

- Tailored lengths and diameters

- Polished, sandblasted, or pickled finishes

- Beveled or square-cut ends

- Tight tolerance control for precision installations