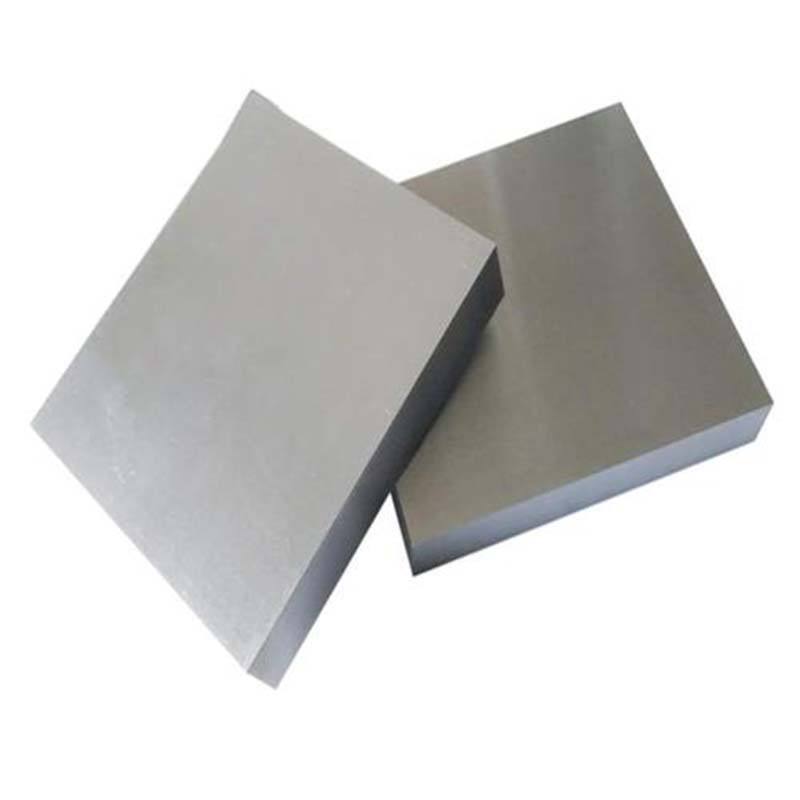

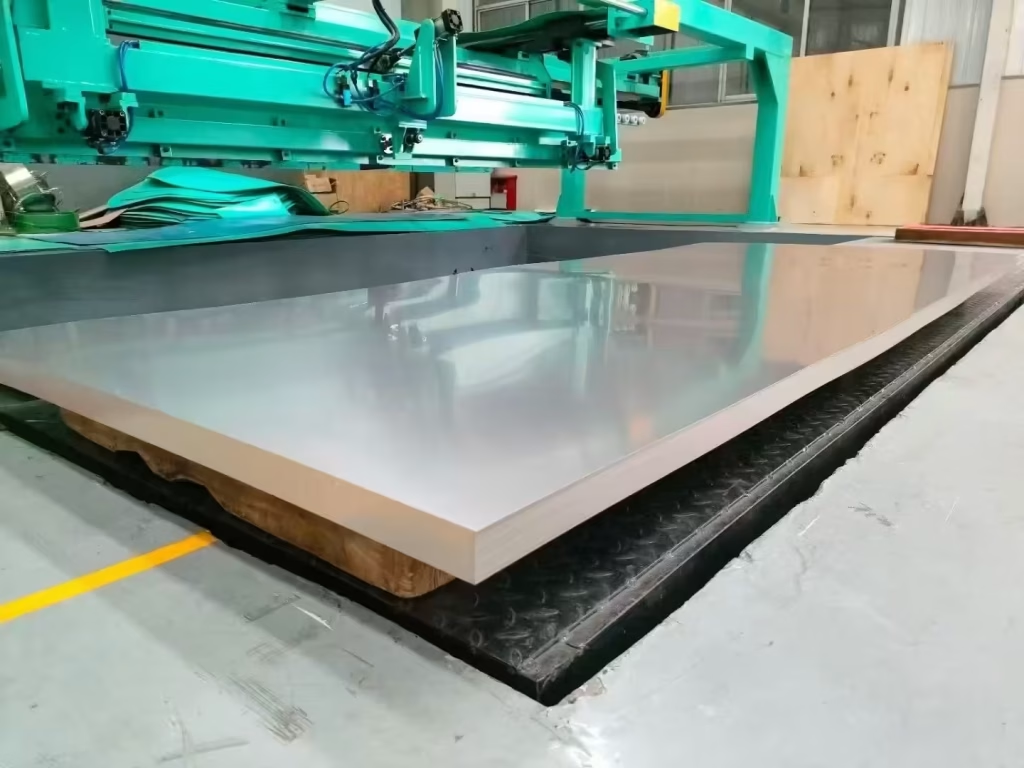

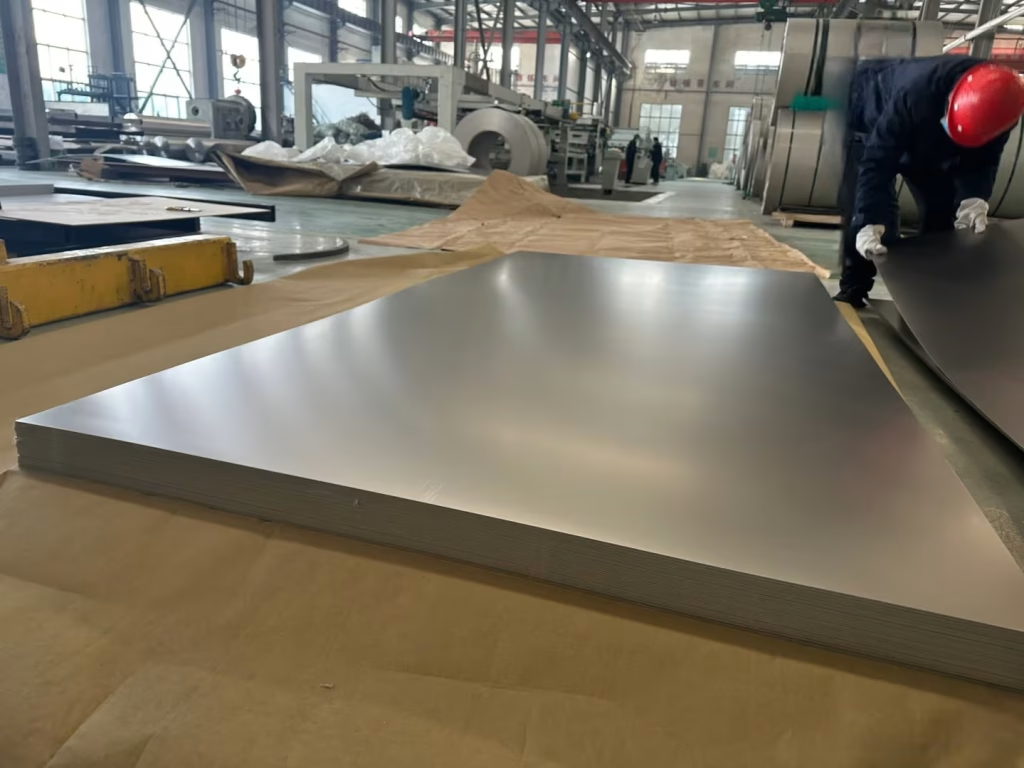

Titanium plate / sheet

💰 Direct Factory Pricing

Work directly with the manufacturer and skip unnecessary markups. Our factory-to-customer model ensures the most competitive titanium pricing, giving you a stronger margin advantage.

🚀 Fast and Flexible Delivery

With well-managed stock and efficient air freight partnerships, we deliver on your schedule — whether it’s a bulk shipment or a single urgent order. No minimum order quantity (MOQ) required.

🧾 Certified and Transparent Quality

Operating under ISO 9001:2015 certification, every batch is backed by a Mill Test Certificate (MTC). We also welcome third-party inspections to verify material integrity and compliance.

|

Grade |

GR1, GR2, GR3, GR4, GR5, GR7, GR9, GR11, GR12, GR23, etc. |

|

BT |

BT1-00, BT1-0, BT1-2, ОТ4-1, BT6, ПТ-7М, BT3-1, ПТ-3В, BT6Cetc |

|

Size |

0.5-100mm |

|

Standard |

ASTM B265, ASTM F136, AMS 4900, AMS 4901, AMS 4902,AMS 4911, AMS 4919, AMS 4914 |

|

ГОСТ 22178-76, ГОСТ 30522-97 | |

Engineered for Performance and Value

Shaanxi Hanye Iron and Steel Co., Ltd manufactures and supplies premium titanium plates and sheets designed for demanding industrial, aerospace, and medical environments.

With ISO 9001:2015 certification, advanced rolling lines, and rigorous inspection systems, we deliver titanium materials that combine exceptional reliability, dimensional accuracy, and cost efficiency.

1. Material Selection & International Standards

Available Grades

- Commercially Pure (CP) Titanium (Gr1, Gr2, Gr3, Gr4): Offers outstanding corrosion resistance and excellent ductility — ideal for chemical processing, marine structures, and general industrial use.

- Titanium Alloys (Gr5, Gr7, Gr9, Gr23, etc.): Engineered for superior strength, light weight, and durability in aerospace, medical, and high-performance engineering applications.

Standards & Compliance

Our titanium sheets and plates are produced in strict adherence to recognized global standards, ensuring full material compatibility and traceability.

- Primary: ASTM B265

- Biomedical: ASTM F136

- Aerospace: AMS 4900, 4901, 4902, 4911, 4914, 4919

- Optional Standards: JIS, DIN, GOST, ISO — available upon request

2. Customization & Fabrication Capabilities

We provide custom-tailored titanium plate and sheet solutions to meet specific project dimensions and fabrication needs.

- Thickness Range: 0.5mm (0.02″) – 100mm (4″), available in customized widths and lengths for optimal material utilization.

- Surface Treatments: Pickled, bright annealed, mirror-polished, or application-specific finishes available.

- Precision Processing: Using laser, waterjet, and plasma cutting, we achieve accurate tolerances and clean edges, delivering ready-to-use components that minimize in-house machining and reduce cost.

3. Advanced Production & Quality Control

Manufacturing Technology

- Hot and Cold Rolling: Ensures consistent flatness, uniform grain structure, and excellent surface finish.

- Controlled Heat Treatment: Annealing, solution treatment, and aging cycles optimize mechanical strength and microstructural stability.

Quality Assurance

Every batch undergoes:

- Ultrasonic (UT) and other NDT testing for internal soundness

- Comprehensive mechanical, chemical, and dimensional inspections

- A complete Mill Test Certificate (MTC) for full material traceability and performance verification