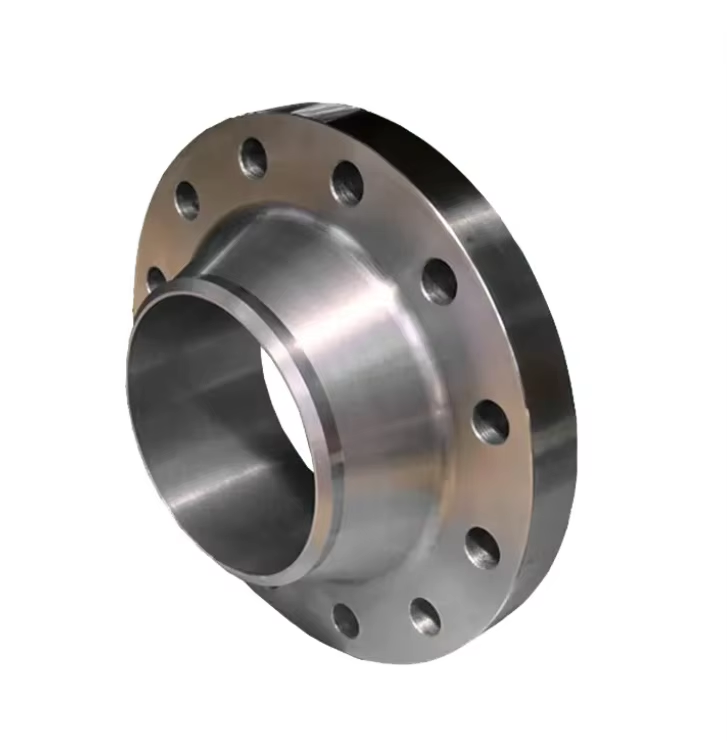

Titanium flange

💰 Direct Factory Pricing

Work directly with the manufacturer and skip unnecessary markups. Our factory-to-customer model ensures the most competitive titanium pricing, giving you a stronger margin advantage.

🚀 Fast and Flexible Delivery

With well-managed stock and efficient air freight partnerships, we deliver on your schedule — whether it’s a bulk shipment or a single urgent order. No minimum order quantity (MOQ) required.

🧾 Certified and Transparent Quality

Operating under ISO 9001:2015 certification, every batch is backed by a Mill Test Certificate (MTC). We also welcome third-party inspections to verify material integrity and compliance.

|

Grade |

GR1, GR2, GR3, GR4, GR5, GR7, GR9, GR11, GR12, GR23, etc. |

|

Size |

Customizable |

|

Standard |

ASTM B 363, ASME SB 363, ASTM B348, ASTM B381, ASTM F67, AMS 4928 |

Direct from the Manufacturer

At Shaanxi Hanye Iron and Steel Co., Ltd, we specialize in producing high-quality titanium flanges that deliver long-lasting, leak-proof performance across industries from chemical processing to aerospace.

Certified to ISO 9001:2015, we combine precision machining, factory-direct pricing, and global logistics to give your business a competitive edge.

What Sets Us Apart

💰 Direct-from-Factory Advantage

Get the best price without intermediaries.

We supply all standard types — welding neck, slip-on, threaded, socket weld, and blind flanges — plus fully customized variants like long neck or reducer flanges.

🧾 Proven Quality Assurance

Every flange is produced from ASTM B381 forgings or ASTM B348 bars, then CNC-machined to meet ASME B16.5/B16.47 tolerances.

All undergo NDT (UT/RT) and come with a Mill Test Certificate (MTC) and full traceability. Third-party inspection is available upon request.

📦 Fast & Flexible Supply Chain

We maintain no MOQ, and most common sizes are stocked for immediate shipment.

With fast air freight and efficient export service, we ensure you receive your order on schedule — wherever your site is located.

⚙️ Precision Machining & Custom Production

Our in-house CNC facilities handle complex geometries, tight tolerances, and custom surface finishes to your specifications.

Available for all pressure classes and facing types (RF, FF, RTJ).

Specifications

Available Range

- Sizes: DN15 (½″) – DN1500 (60″)

- Pressure: PN6 (Class 150) – PN420 (Class 2500)

- Facing: RF, FF, RTJ

Grades Offered

- Gr1, Gr2 (Commercially Pure): Best for corrosive and marine systems

- Gr5, Gr7, Gr9, etc. (Alloys): Superior strength and temperature resistance

Conformance

- ASME B16.5 / B16.47

- ASTM B381 / ASTM B348

- Optional standards: JIS, DIN, GOST, ISO